| Email: | .com |

| Tel: | +86-311-6 |

| Fax: | +86-311-8 |

| Skpye: | |

| Add: Hebei Province, China | |

|

|

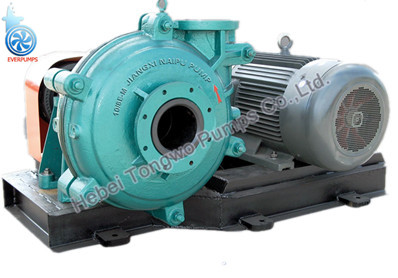

Introduction:

Model Explanation:

TMM-8E

T: our company

M: Middle concentration

M: Metal lined

8: Discharge size (inch)

E: Frame type with maximum power

Introduction of Slurry Pump ---- TMM Series

TMM Series slurry pump is mainly using for handing strong abrasive, high density slurries and low density, high head slurries in the metallurgical, mining, coal, power, building material and other industrial departments etc.

The features of this kind of slurry pump

The frame plates of this kind of slurry pump have replaceable wear-resistant metal liners. The impellers are made of wear-resistant metal. The frame plate liner and impeller for TMM pump are adoptable of hard metal only.

Bearing assembly of this kind of slurry pump use cylindrical structure, adjusting the space between impeller and front liner easily, being removed completely when being repaired. Bearing assembly use grease lubrication.

The shaft seal of this kind of slurry pump could use the packing seal, expeller seal and mechanical seal. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Here are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices.

Wide performance, good NPSH and high efficiency. The pump of this type may be installed in multistage series to meet the delivery for long distance.

Main application of this kind of slurry pump

This kind of slurry pump mainly applies in coal washer processing, handling with the fine ore and tailings in metal mine, handing combined bottom and fly ash in a thermal power station etc

TMM Series Slurry Pump Performance Chart

|

Pump Model |

Allowable Max. Power(kw) |

Clear Water Performance |

|

|||||

|

capacity Q |

Head H(m) |

speed n(r/min) |

Max.eff. η% |

NPSH (m) |

Impeller Dia(mm) |

|||

|

m3/h |

l/s |

|||||||

|

TMM-8E |

120 |

540-1440 |

150-400 |

14-60 |

600-1000 |

73 |

4-10 |

549 |

|

TMM-8R |

300 |

|||||||

Note: 1.Quantity range recommended:50%Q’≤Q≤100%Q’(Q’Appropriate to capacity at highest efficiency point).

2.NPSH:appropriate to point Q recommended at highest speed.

Related Products: